ChP

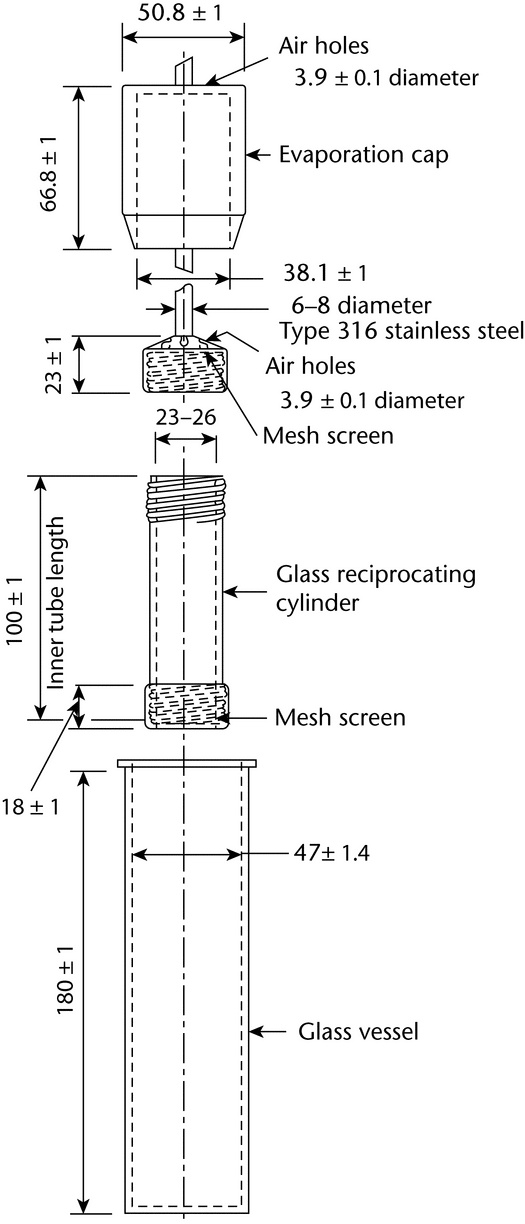

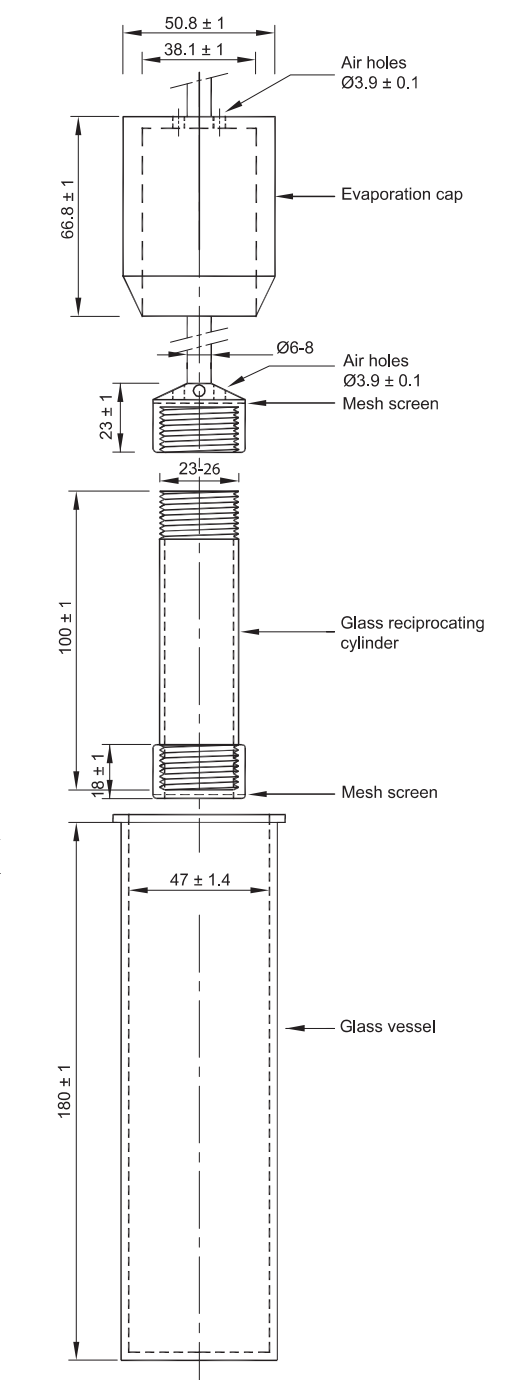

Vessel

Inner diameter: 47mm±1.4mm

Height: 180mm±1mm

Height of anti-volatile cover of vessel: 66.8mm±1mm

Material: made of hard glass or other suitable inert materials

Shaft

Reciprocating shaft diameter: 6.0mm-8.0mm

Inner tube

Inner diameter: 23mm-26mm

Height: 100mm±1mm

Top nut height: 23mm±1mm

Bottom nut height: 18mm±1mm

Material: made of hard glass or other suitable inert materials

Motor

Specified range of reciprocating frequency: within ±5%